Cosmetics - Supply Chain

- Raw material sourcing – seasonal and specialized ingredients

- Product Traceability

- Temperature controlled transportation – cold chain

- Multi Tier sourcing and Demand visibility in the supply chain

- Complex distribution challenge

Lot Number and Expiration control:

TPSynergy has configurable rules that will ensure suppliers provide batch number and expiration dates for the shipments ASN they are creating. TPSynergy triggers alerts and notifications when there are expired products being transacted in the supply chain.

Suppliers in cosmetic industry might be required to provide necessary documentation along with their shipments. This could be Test results, Batch records, Log Books , customs clearance etc. TPSynergy provides a comprehensive supply chain document management system that ensures suppliers do upload necessary documents before the ship the consignment. Also these documents are routed into a Block Chain network for added security and logging.

Ingredients Traceability:

Entire travel history of the raw material and finished products need to be tracked with history.

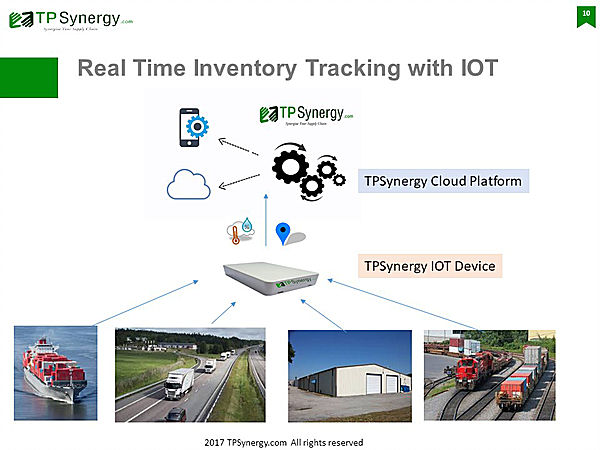

TPSynergy uses Internet Of Things (IOT) enabled devices to get real time updates on the location of the shipments. This helps greatly in the event of any audit.

Many of the cosmetic items need to be maintained at certain temperature (cold chain)through out its journey in the supply chain. Detailed temperature logging is needed when the shipments are transported. TPSynergy uses its Internet of Things (IOT) enabled devices to track the temperatures and humidity in real time. Alerts are created in advance before things go out of control so that corrective actions can be taken.

How it benefits your supply chain

- Ready made supply chain solution that meets many industry regulations

- Visibility and control ensures on time delivery

- Digitized collaboration platform connects Raw material suppliers, contract manufacturers, transporters and 3PL providers.

- Temperature logged and synchronized to cloud ensures real time monitoring to avoid wastage.

- Overall supply chain improvement due to collaborative execution

Are you interested? Do you have any questions or comments?

We'd love to hear from you!

+1 - 512-270-4965

Supply Chain

Supply Chain Control Tower

Order Management

Advance Ship Notice

Electronic Integration

Inventory Visibility

Internet of Things (IOT)

Electronic Invoicing

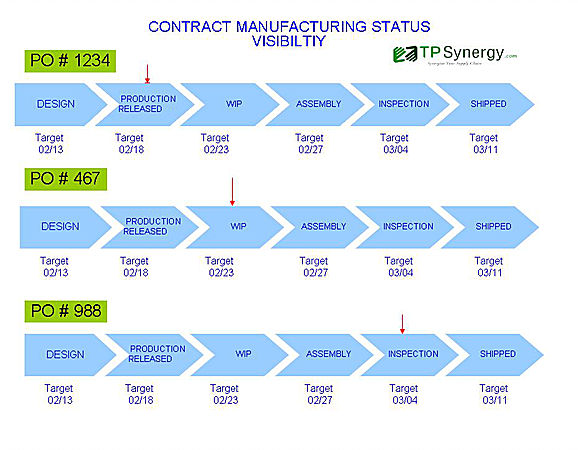

Contract Manufacturing

Efficient Receiving

Document Management

Quality Management

Real Time Monitoring

Block Chain Security

Inbound Freight Consolidation

Forecast Collaboration

Mobile Apps for Supply Chain

EDI Integrations

EDI For Amazon

EDI For Grainger

EDI For Fry’s Electronics

EDI For Home Depot

EDI For WayFair

EDI For BJ’s Audio

EDI For Cardinal

EDI For TJMax

EDI For Marshalls

EDI For Kohl

EDI For Sephora

EDI For Zappos

EDI For Royal Canin

EDI For General Mills

EDI For Pepsi

QuickBooks EDI

Shopify DropShip

BigCommerce DropShip

SKUVAULT EDI

StichLabs EDI